updraftplus domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /home/oliveira/domains/osvard.com/public_html/wp-includes/functions.php on line 6114all-in-one-wp-security-and-firewall domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /home/oliveira/domains/osvard.com/public_html/wp-includes/functions.php on line 6114“We deliver trusted process safety solutions that protect your operations and ensure compliance, leveraging our global expertise to minimize hazards and prevent damage“

HOW WE HELP CLIENTS

We offer specialized services in process safety engineering and risk assessment across various industries, ensuring adherence to quality and safety standards. Our focus is on developing process safety and risk management systems that help you meet local, state, and federal regulations, thereby preventing damage and minimizing hazards. Drawing upon our extensive global industry experience, we deliver tailored process safety solutions to meet your operational requirements.

Process Hazard Analyses and Risk Assessments

Our team of consultants conducts process hazard analyses and delivers assessment recommendations tailored to diverse industries. Our services are designed to yield rapid and precise results, significantly reducing occupational and operational risks. Process hazard analyses are pivotal for effective process safety management, and we utilize various techniques including:

Hazard Identification (HAZID)

We have accumulated extensive experience in identifying and mitigating risks across a wide range of industries, including oil and gas, and petrochemicals. Our team effectively maps out potential hazards associated with processes and operations. The HAZID is complemented by our team’s ability to integrate findings into practical safety measures and workflows.

Hazard and Operability study (HAZOP)

Our consultants provide specialized Hazard and Operability study (HAZOP) services in complex systems. Our expert team facilitates to pinpoint unsafe conditions or inefficiencies, helping in the early detection of hazards, ensuring that safety from the initial stages of project development.

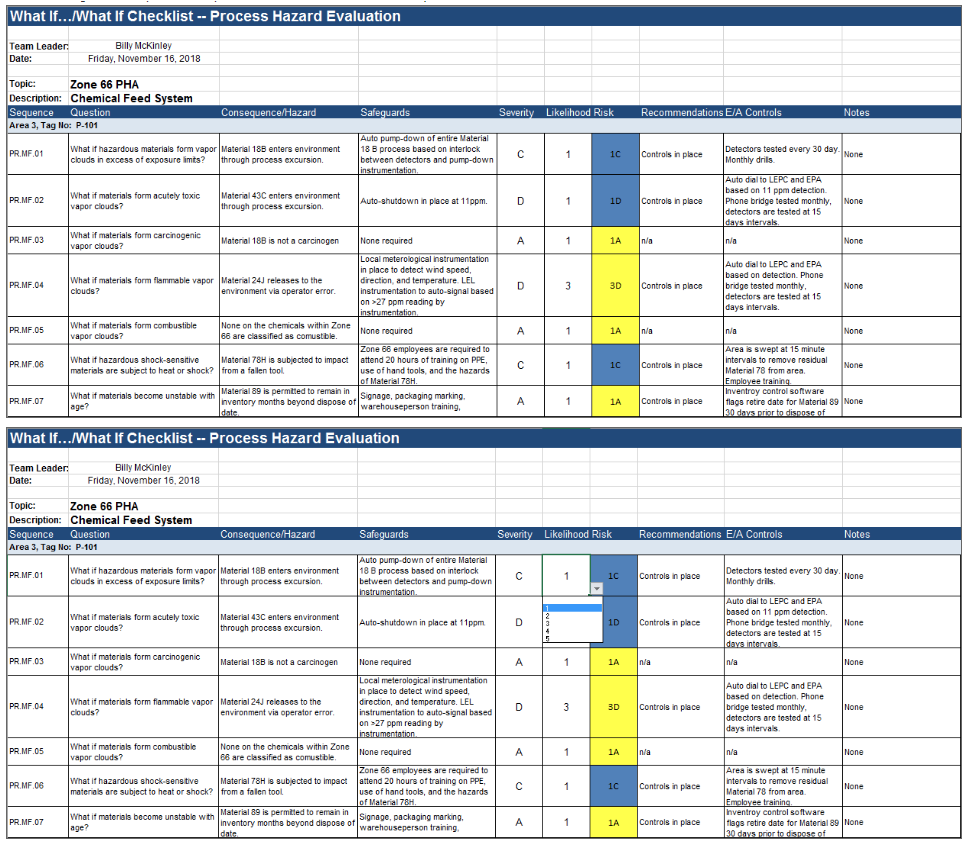

What-if/CheckList

What-if/Checklist analysis evaluates potential risks in industrial processes. This service uses a structured brainstorming method to generate and analyze “what-if” scenarios, where potential failures and their consequences are examined. The checklist component complements this by systematically reviewing operations against a set of safety and performance criteria to ensure no aspect of the system is overlooked.

Layer of Protection Analysis (LOPA)

Through LOPA, our team conducts a detailed analysis to establish the likelihood of hazard scenarios and the potential consequences, enabling the evaluation of the effectiveness of safety barriers already in place. LOPA is valuable in high-risk industries such as chemical processing, oil and gas, and pharmaceuticals.

Consequence Analysis (CA)

We provide Consequence Analysis helps in accurately determining the severity of potential accidents and facilitates effective mitigation strategies. We helps clients visualize the extent of impacts and plan emergency response procedures accordingly.

Safety Integrity Level (SIL) Classification

Our experts evaluate the risk reduction needed and the reliability required of the safety systems in place to mitigate those risks, ranging from SIL 1 (lowest) to SIL 4 (highest). We helps clients to align their safety systems with international standards, enhancing overall safety and compliance.

Alarm Rationalization

We employ a methodology to assess and categorize alarms based on their priority. Our services help clients avoid the common pitfalls of alarm flooding, implementing best practices for alarm management lifecycle, from initial design and rationalization to maintenance and continuous improvement.

Failure Mode and Effects Analysis (FMEA)

We can identify potential failure points in clients processes, assess their risks, and implement effective mitigation strategies to enhance safety, reliability, and efficiency, ultimately ensuring compliance with regulatory standards and minimizing operational costs.

Process Safety Engineering

Our process safety engineering services encompass all aspects of process safety design package from basic engineering to execution phases. This includes:

Safety Distances

Overpressure Protection

Venting Protection

Disposal and Flare Systems

Hazardous Area Classification

Action & Passive Fire Protection

Fire and Gas Detection systems

Fireproofing

Escape Route and Safety Equipment Layout

We are committed to providing efficient and effective process safety and risk management services, aiding in the meticulous management of process facilities. Our industry experts guide you through each step of the risk management process and assist in developing a robust safety strategy for your operations.

Connect with OSVARD today